Title: Microsoft Team Harnesses AI-Powered Diffusion Model to Revolutionize Materials Science and Advance Battery Technology

Microsoft has made a groundbreaking breakthrough by leveraging its innovative diffusion model to transform the landscape of materials science. The team’s achievement not only paves the way for significant advancements in battery technology but also opens up new possibilities for creating innovative materials that could have far-reaching impacts on various industries.

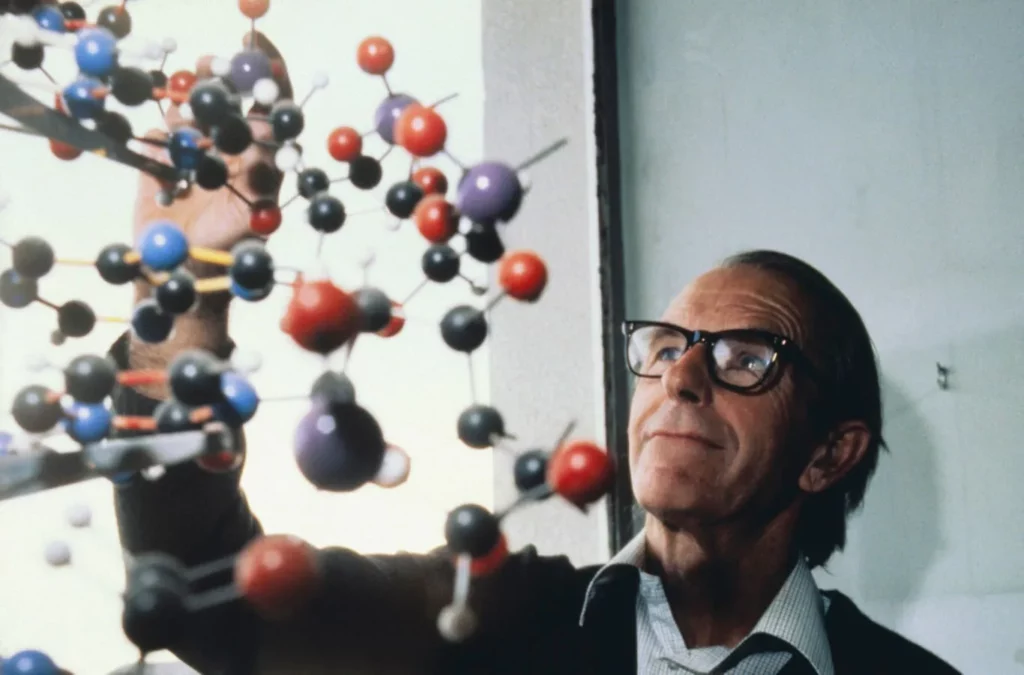

The diffusion model, as explained by John Werner, allows researchers to predict and design novel compounds with unique properties, such as enhanced strength and corrosion resistance. This technology has vast implications for the development of more efficient and sustainable energy storage solutions.

For instance, the Microsoft team’s work in this area is focused on innovating lithium-ion battery designs. These batteries are critical components in modern smartphones, electric vehicles, and other applications. However, traditional lithium-ion batteries rely heavily on scarce materials like lithium, which poses significant environmental and social concerns.

The researchers at Microsoft have successfully reduced the amount of lithium required in a battery design by as much as 70%. This achievement is substantial, considering that it’s challenging to find alternative sources for this essential material.

Furthermore, AI-powered diffusion models can potentially unlock new opportunities for sustainable energy storage solutions. By exploring novel compounds with enhanced properties, we may be able to create more durable and efficient batteries that don’t rely on scarce materials.

In the context of brass, the team’s discovery sheds light on its unique characteristics. Initially, it was thought that the arrangement of zinc and copper atoms would result in a uniform pattern. However, this is not the case due to the compositional disorder caused by the random swapping of atoms within the crystal lattice.

The Microsoft diffusion model can also be used to predict the properties of brass based on its composition. As Werner points out, the softness of brass stems from the arrangement and interaction between copper and zinc atoms. The addition of more zinc can lead to even softer material, highlighting the critical role that compositional disorder plays in this process.

This innovative technology has far-reaching implications for various industries, including aerospace, electronics, and automotive manufacturing.

Source: www.forbes.com